Color masterbatch is made by using PE and PP as carriers, selecting inorganic, organic, and various special effect pigments, dyes, and suitable additives for processing. We can customize products for customers, produce products that meet their usage requirements and have good cost-effectiveness according to their needs and actual production situation. Widely used in packaging films, bottles, caps, hoses, various containers and toys, household appliances, office supplies, automotive accessories, and various building pipes, suitable for various processing technology fields such as extrusion, blow molding, casting, injection molding, etc.

Add proportion

Mix the masterbatch and raw resin in a ratio of 1:25-1:50 (depending on the specific requirements of the product), mix evenly, and dry before use.

packing

Paper plastic composite bags, PE valve pockets, PE adhesive bags, and PE transparent valve pockets each have a net weight of 25KG. Please store in a dry place.

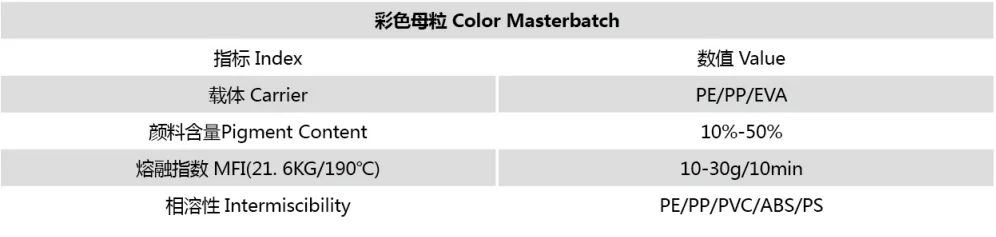

physical property

application area

In the processes of blow molding, injection molding, wire drawing, and tube pulling.